Redefine Color Management with Ink Dispensing Technology

Streamline ink management, reduce waste, and achieve accurate batch consistency with cutting-edge ink dispensers.

With an ink dispenser program, printing companies can break free from outdated methods, work smarter, and reduce applied costs. Color management becomes more intuitive and environmentally friendly with ink dispensing technology, delivering unmatched precision and consistency to the pressroom.

Ink Dispensing: Modernizing color management in the Pressroom

The printing industry has seen remarkable advancements over the years, and ink dispensing technology is at the forefront of this transformation. Gone are the days when managing ink was a labor-intensive process filled with inconsistencies and waste. Today, ink dispensing systems are revolutionizing color management in pressrooms worldwide. Let’s explore how ink dispensing is modernizing color management and why it has become an essential tool for today’s printing professionals.

Accurate and Repeatable Spot Colors

One of the most significant contributions of ink dispensing technology is its ability to deliver accurate and repeatable colors. Ink dispensing technology improves workflows by maintaining color consistency and eliminating the uncertainty that once disrupted print runs. In the past, achieving consistent color across multiple print runs required extensive manual mixing and constant adjustments, often leading to variability and errors. Today, modern ink dispensers eliminate these challenges by automating the process with precise formulations and measurements.

Smart software helps create custom ink blends to exact specifications, ensuring every batch meets the desired color standard. This precision doesn’t just enhance the final product—it builds trust with clients who rely on flawless consistency for their brand materials.

Efficient Ink Management

Efficiency is a cornerstone of today’s pressroom operations and ink dispensing systems have made significant strides in optimizing ink management. Traditional methods often involved overestimating ink requirements, leading to excess inventory and waste. Ink dispensers enable pressrooms to prepare the exact amount of ink needed for each job, minimizing overproduction and cutting costs.

Automated dispensing systems also streamline workflows, saving valuable time for press operators. Instead of spending hours manually mixing and measuring inks, operators can focus on other critical tasks, boosting overall productivity. The result? Faster turnaround times without compromising quality.

Reduced Ink Inventory and Waste

Sustainability is increasingly important in the printing industry, and ink dispensing technology plays a vital role in reducing waste and conserving resources. By producing only the required amount of ink for each job, dispensers significantly cut down on leftover materials that would otherwise go to waste. This not only minimizes environmental impact but also lowers disposal costs for pressrooms. With precise ink management, pressrooms no longer need to stockpile large quantities of pre-mixed inks. Instead, they can maintain a consolidated inventory of base colors and additives, freeing up storage space and reducing the risk of obsolescence. This lean approach to inventory management aligns with modern sustainability goals while improving operational efficiency.

Consistent Batch Quality

Batch consistency is crucial for upholding high standards in printing, especially for large-scale or repeat projects. Ink dispensing systems guarantee that every batch is identical to the last, eliminating variability and ensuring uniformity throughout the print run. This consistency is achieved through precise formulations and automated processes that remove the guesswork from ink preparation.

For pressrooms handling complex jobs or working with demanding clients, this level of reliability is invaluable. Consistent batch quality translates to fewer errors, less rework, and greater customer satisfaction—key factors in maintaining a competitive edge in the industry.

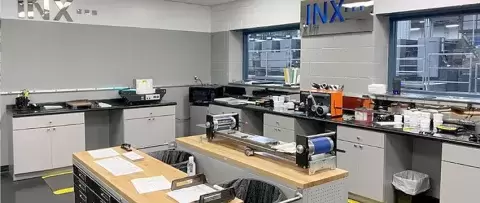

Drive Print Efficiency and Quality with INX Ink Dispensers

Powered by leading-edge partners like GFI, Novaflow, and HMJ Tech, the INX Ink Dispenser Program combines versatility and reliability to transform your print operations.

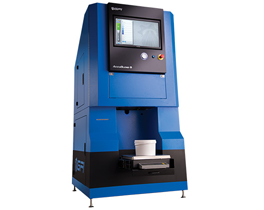

GFI AccuBlend-HV™

GFI AccuBlend-HV™ is engineered for small to medium-sized offset and UV offset, dry offset, metal decorating, and highly viscous paste-type inks. Offering batch precision up to 30 pounds, with optimal accuracy in the 5–10-pound range, it’s fast, reliable, and built to meet tight schedules. Dispensing just-in-time color in the right amount, it’s always steps away from your press and delivers precise spot colors. A hybrid model is also available to achieve UV flexo spot-color accuracy with ease.

HMJ Tech A-200/255 and A-300/355

These dispensers were built to fill a gap—one that INX and HMJ Tech identified together. Compact, efficient, and engineered for both small and large batch production, these machines are designed to simplify and speed up your workflow. With innovations like automatic cleaning systems and precision dispensing, these dispensers provide game-changing printing solutions.

HMJ TECH HMJ-A200 may be small in size, but it’s big on features. The A200 is an industrial-grade dispenser that fits anywhere but performs like the big machines. With fully automated cleaning and single-point dispense, it handles up to 14 ingredients, giving you clean, predictable results every time

HMJ TECH HMJ-A255 is designed for those who need more—this dispenser can handle up to 24 ingredients and can be configured with pails, drums, or totes. It uses a 2-stage valve for precision, making a 40-pound batch in just 3.5 minutes with an accuracy of 0.0004 pounds (0.2 grams).

HMJ TECH HMJ-A300 provides high performance in a compact design. This pail dispensing system uses a 3-stage valve to create a 40-pound batch in 2 minutes. It’s built for speed, consistency, and precision, with the ability to handle up to 32 ingredients.

HMJ TECH HMJ-355 is perfect for operations with big ambitions. The A355 handles batches up to 300 kg, using a dual-scale configuration for ultimate accuracy. With the ability to accommodate up to 28 ingredients, this system is perfect for high-output environments.

NovaFlow N20 and N50 Series

Elevating flexo printing with water- and solvent-based ink systems, these dispensers are engineered for consistent, vibrant results.

NovaFlow N50 is built for the toughest environments. The Novaflow N50 thrives in solvent-laden, Class 1, Division 1 explosive settings. It gives you the power to choose between speed and accuracy with its two-stage dispense valve. Need print flexibility? It handles multiple batch sizes—from 5 to 55 gallons with standard scales—and can be customized for larger batches. Whether you’re drawing from buckets, drums, or bulk containers, this dispenser adapts to you.

NovaFlow N20W is where print flexibility meets precision. Its two-stage dispense valve lets you pick accuracy or speed, and the standard scales handle multiple batch sizes. Need to produce one-gallon batches? The automatic scale indexing option makes it a breeze. Pumping raw materials from buckets, drums, or bulk containers? It's all possible with the N20W.

Unmatched Support from Ink Specialists

Ink is a consumable product that can be managed to reduce costs and increase operational efficiency. For many of our customers, ink management, mixing and color matching isn’t their core business so exploring the benefits of inplant ink operations is a worthwhile exercise.

With INX as your ink and color partner, we are able to ensure that your ink is performing at its peak efficiency on each and every substrate on which you are printing. From the start, our team helps assemble and assists in configuring the perfect solution for your needs. Should challenges arise, our ink specialists provide seamless troubleshooting and support to keep your operations running smoothly.

DOWNLOAD

Ink room management solutions that increase your efficiencies and reduce cost

Download Brochure

Transforming the Pressroom

Ink dispensing systems are not just tools; they are catalysts for change in the printing industry. By modernizing color management, they empower pressrooms to operate more efficiently, reduce waste, and deliver superior results. From accurate and repeatable colors to optimized inventory and improved sustainability, the benefits of ink dispensing technology are undeniable.

As the printing industry continues to evolve, adopting advanced ink management solutions will be essential for staying ahead. Whether you’re a small print shop or a large-scale operation, investing in ink dispensing technology is a step toward a more efficient, sustainable, and competitive future.