Color Standards: Taking The Chaos Out of Color

A Valuable Backbone for Printing Excellence

The quest for quality color is an essential part of successful print production, and the thoughtful use of color standards can increase quality, eliminate spoilage, and increase customer satisfaction. While the standardization of color in printing is nothing new, changes in that space – refinements, new tools, new approaches – as well as the controllability of digital printing, have served to bring printed colors increasingly close to their mathematically-measured ideals.

While it is important to understand the value that color standards can bring to print production, they are not the only thing standing between print producers and absolute color chaos. Color standards are also utilized in the development of color management, RIP, and workflow management software – the tools that help PSPs (Print Service Providers) automate color control. For instance, many current RIPs for wide-format digital printing have G7 functionality already built-into them. Further, manufacturers of inks and substrates pay close attention to color standards. Factors such as batch-to-batch consistency in process colors and consistent whiteness levels in, for instance, paper, are essential for quality print results.

In this way, it can be said that color standards are somewhat of a backbone: a theoretical structure around which inputs, tools, and outputs can be positioned. Common goals and common approaches, to deliver exemplary results.

Color Standards: Many Goals, Many Uses

The development of color standards has not had a neat, linear trajectory. As with any science – and color control is a science – the world of color is typified by a panopoly of acronyums, different approaches and theories, iterations and updates to existing standards, and even new, game-changing approaches rife with controversy.

SWOP (Specifications for Web Offset Publications), hatched in the early 1970s, was one of the earliest printing-specific color standards. The FOGRA39 standard according to the International Color Consortium, provides a characteriation data set that, “represents the colors of a typical print made by commerciaal offset litho on gloss or matter coated paper.” Its goal is to present a production target for offset printing using the CMYK color set.

While groundbreaking, SWOP and FOGRA39 are limited to a specific type of printing for a specific range of applications, printing, including all its processes, is much bigger. Expanding on the concept, the International Standards Organization’s 12647] standard was created with seven individual sub-standards, addressing the process and color conditions for print disciplines such as offset and heatset presses, flexography, rotogravure, and screen printing.

With the rise of digital printing, color standards are changing and being developed. For instance, ISO/PAS 15339 is a standard under which the capabilities of digital press devices are tested to ensure they meet specified color space requirements. Surely, purchasing a press that has already been certifed as color-capable, gets PSPs that much closer to achived desired color with fewer complications.

G7 certification has had a stong affect on color quality and how PSPs achieve it. G7 can be pictured as the hub of a wheel, where all colors blend into neutral grey. By focusing on achieving a true neutral grey at the hub, then all colors, as they follow the spokes of the wheel outward, will also be correct. G7 can also be used to harmonize devices, and to work across platforms. This approach is also seen, says Ray Weiss, vice president if eLearning and certifications at PRINTING United Alliance Weiss says, in the soon-to-be released ISO 15339 standard, which also approaches color management through neutral greys. “There is a realization,” he says, “that if grey can be right, it can solve all the issues.”

CONTACT

Solutions to reduce costs, speed products to market, and improve clients' brand image.

Contact a Color Management Rep

The Value of ICC Profiles

The measured color appraoch that is most commonly used in printing – particularly digital print production – is color profiling. Profilies are specific measures that compensate, in printing, for specific properties of color space, printing devices, and media types. While profiles can help compensate for color limitations, the true color capability of a printing device, say, an wide-format inkjet device, is limited by the color space within which it is operated. According to, choice of a correct color space for the capabilitites for a printing device is paramount. Weiss says that many companies work within relatively small color spaces, and hence sacrifice some availale color capability. A new CMYK color space, he says, known as PRINTWIDE, allows for an expansion of CMYK capabilites. According to Idealliance, then new space is designed to encompass the gamut of “virtually all inks for colorants in all known color printing systems.” Result: A much less limited color gamut.

Practical Use of Color Standards

In additonal to paying strong attention to standards in order to achieve theoretically-correct results for ink on paper, printers must also understand lighting standards. When printed results are designed in one space but produced and viewed in another, significant differences can occur. For instance, a well-known brand color, even if it was produced using the methodologies of color standards, can appear incorrect depending on the lighting conditions – for instance, a retail store – where it is displayed. “What you don’t understand can come back to bite you,” Weiss says.

In color, understanding is key, and understanding and implementing standards, achieving color management certification, and demonstrating mastery in meeting customer needs, PSPs operate a level high in performance and low in risk. Reliable, repeatable results are commonplace.

How Standardized Color Brings Value

Beyond meeting targets and achieving required results, it is essential to understand that exemplary color, archived through the procedures and defined spaces of color standards, can also have a profound benefit on the bottom line. The ability to achieve color faster means less waste, fewer minutes (or hours) spent adjusting color, more productive time for presses, the ability to do color-consistent reorders.

Like the laws and codes that guide construction, color standards are a guiding force in printing production, creating a strong foundation upon which quality, exemplary results, and repeatability become commonplace, free from chaos or collapse.

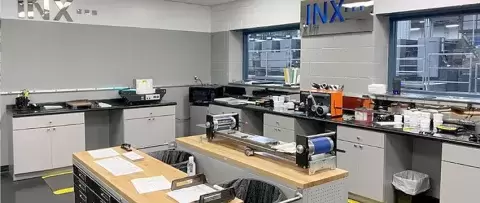

For more information on managing color in your printing business, INX offers numerous color resources online, all designed to help you maximize color and achieve (or exceed) expected quality.