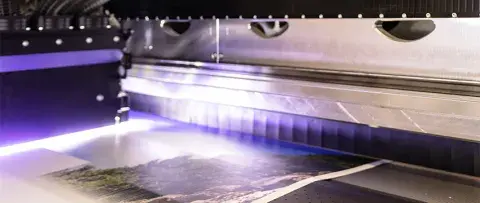

Printing Problems on Press, and How to Avoid Them

Press Troubleshooting with simple, effective technical printing solutions.

Printing problems on press steal your time and stall your growth. They often arise from imbalance—fading colors, ink scumming, misting, or improper ink to water ratios—all of which can derail your print jobs. When one component is off, the entire process suffers. Fortunately, there are practical solutions that can not only make printing smoother and smarter, but also more reliable.

Why Printing Problems Happen

Truth is, printing problems on press are often silent productivity killers yet, many companies continue to battle the same recurring problems. These aren’t random hiccups—they’re preventable signals of insufficiencies in your process. By identifying the causes and solutions, you can break the cycle and keep your press operating at its best. Ready to take control? Let’s review some common printing problems, their causes, and our recommended solutions.

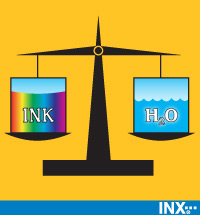

Ink to Water Imbalance: The Root of It All

When ink and water aren’t working together, the result leads to dull colors, uneven prints, and wasted time.

What’s Causing Ink to Water Imbalance?

- Fountain solution too acidic or warm: A rogue pH or heat spike destabilizes your ink.

- Quick, uncalibrated adjustments: Knee-jerk reactions in your process can throw everything off balance.

- Uncontrolled pressroom conditions: Heat, humidity, and environment can turn prints from flawless to flawed.

The Ink to Water Balance Solution

- Monitor your pH: Your fountain solution sets the tone. Keeping pH in check is a mandatory step in avoiding common printer problems.

- Adjust with precision: Tiny tweaks matter. Adjustments in fountain solutions make a difference.

- Control your pressroom environment: Even slight fluctuations in temperature and humidity affect ink and water performance.

Scumming in Printing: A Three-Step Fix

When your ink-to-water balance is off, the result is often scumming–ink spreading where it shouldn’t. It’s a telltale sign of inefficiency in the process and an indicator that something’s broken.

What’s Causing Scumming?

- Fountain solution overload: An improper ink-to-water ratio can flood the press with too much ink.

- Leftover residue: Even small amounts of residue from previous jobs can affect the quality of the print and cause ink to go places it shouldn’t.

- Rollers out of sync: Misaligned or worn rollers often lead to ink being applied unevenly, causing scumming.

The Scumming Solution

- Fine-tune the fountain solution: Start with adjusting the pH—it’s key to ensuring that the ink flows where it should.

- Deep-clean your rollers and plates: Cleanliness matters. Remove any residue thoroughly to ensure smooth ink application.

- Reset your rollers: Rollers need to be properly aligned to prevent unwanted ink spread. This ensures better performance and a reduction in scumming.

Ink Misting? A Mess You Can Control

Ink floating through the air like confetti? It’s wasteful, messy, and entirely preventable.

What’s Causing Misting?

- Ink that’s too thin or soft: When your ink lacks the right viscosity, it scatters instead of sticking.

- Rollers in overdrive: Speed creates mist—it’s simple physics.

- Misaligned rollers: Uneven roller pressure leads to ink spraying in places it shouldn’t.

The Ink Misting Solution

- Slow down the speed: Reducing press speed allows for more controlled ink application.

- Stabilize your ink: The right additives, like retarders or dispersants, can help keep ink consistent and smooth.

- Lower the temperature: Cooling down the rollers can prevent the ink from becoming too volatile and spraying out (aka misting).

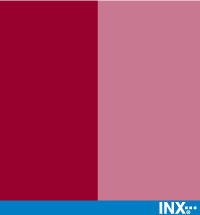

Burnout Issues and How to Fix

Colors fading too quickly? Blacks turning gray, deep blues fading into mediocrity? That’s burnout, and it’s draining your resources.

What’s Causing Burnout?

- Pigments that can’t take the heat: Some pigments simply aren’t built for the job. UV light or high temperatures break them down, leaving your prints flat and lifeless.

- Ink that isn’t curing properly: If ink doesn’t dry right, you’re left with smudges, colors fading, and frustration. It’s a system problem—or a thickness problem.

- Too much ink, too little drying: Thick layers trap moisture, preventing proper drying. The result? Uneven, blotchy prints.

Burnout Solutions

- Switch to UV-resistant pigments and high-quality ink that can handle the heat.

- Double-check your drying system—stop the smudges before they start.

- Go lighter on the ink: Thinner layers dry faster and sharper.

Plate Blinding: The Silent Saboteur

When your plates stop cooperating, it's often due to plate blinding, causing ink to refuse adhesion and leading to dull prints.

What’s Causing Plate Blinding?

- Overly acidic fountain solutions: Excessive acidity can damage the plate surface, making it impossible for ink to stick.

- Sloppy cleaning routines: Residue builds up and blocks ink adhesion.

- Aging or faulty plates: Sometimes, the issue isn’t the process—it’s the plate itself, worn down or damaged over time.

The Plate Blinding Solution

- Neutralize your fountain solution: Balance the pH, balance your prints.

- Clean thoroughly every time: Residue is the enemy. Keep your plates spotless to ensure ink sticks where it should.

- Replace the plate when necessary: If it’s worn out or damaged, replace them. Fresh plates make a difference.

Stay Ahead. Prevent Problems on Press Before They Happen

Printing maintenance isn’t just a task; it’s an investment and your best defense against future problems.

What’s Lurking Beneath Your Printer Problems?

- Neglecting proactive maintenance: Problems get worse when not addressed early.

- Ignoring small signs: Seemingly minor issues can snowball into major disruptions.

- Using outdated materials: Relying on inferior supplies makes things worse.

The Printing Maintenance Solution

- Inspect your press regularly: Even when it looks fine, a closer inspection can prevent headaches later.

- Clean thoroughly: You’ve seen this point a few times, and that’s because routine cleaning is a major key to smooth operations.

- Choose quality supplies, always: Your prints are only as good as the materials you use. Invest in quality for lasting results.

Discover more about Standardized maintenance on printing equipment from INX Experts

Talk to Us

Here’s the good news: understanding the root causes of printing problems like burnout, scumming, misting, and ink-water imbalance puts you in the driver’s seat. Regular maintenance, quality supplies, and proactive troubleshooting are the foundation of vibrant prints.

In the quest for consistency, details are everything. Don’t ignore those small tweaks—they add up. Tackling problems early saves you time, money, and frustration.

If you’re ever in doubt, reach out to an INX expert. Sometimes, a little guidance is all it takes to make sure every print is picture-perfect.

CONTACT

Solutions to reduce costs, speed products to market, and improve clients' brand image.

Contact a Color Management Rep

Need a clear step-by-step review of your printing problem(s)? Access our Free Troubleshooting Guides for quick fixes and tips to keep your press running smoothly.

About INX International: INX International is part of Sakata INX’s worldwide operations with full-service subsidiaries in the Americas, Europe and Australasia. We provide pioneering ink and coating technology with a deep commitment to sustainability – ensuring that we not only deliver superior products, service, and support, but also environmentally conscious printing solutions for commercial, packaging, and digital print applications. INX International – Where color meets consciousness. Learn more at www.inxinternational.com.