6 Best Practices for Color Management in the Press Room

Minimize waste, maximize productivity, and ensure accurate and consistent color

Consistently producing a client’s exact color specifications requires a predictable color management system. As a leading ink and coating supplier with a team of Color Perfectionists, we recommend that our customers incorporate a number of best practices in order to minimize waste, maximize productivity, and ensure accurate and consistent color.

Taking a hands-off approach to color management frequently leads to poor print quality and inconsistent color with negative variations on different packaging substrates which results in poor brand recognition, dissatisfied customers, and additional challenges and costs down the road. For printers and packaging converters, ensuring that their client’s exact color specifications are produced consistently while minimizing waste and maximizing productivity requires a predictable color management process.

What is Color Management and Why is it Important?

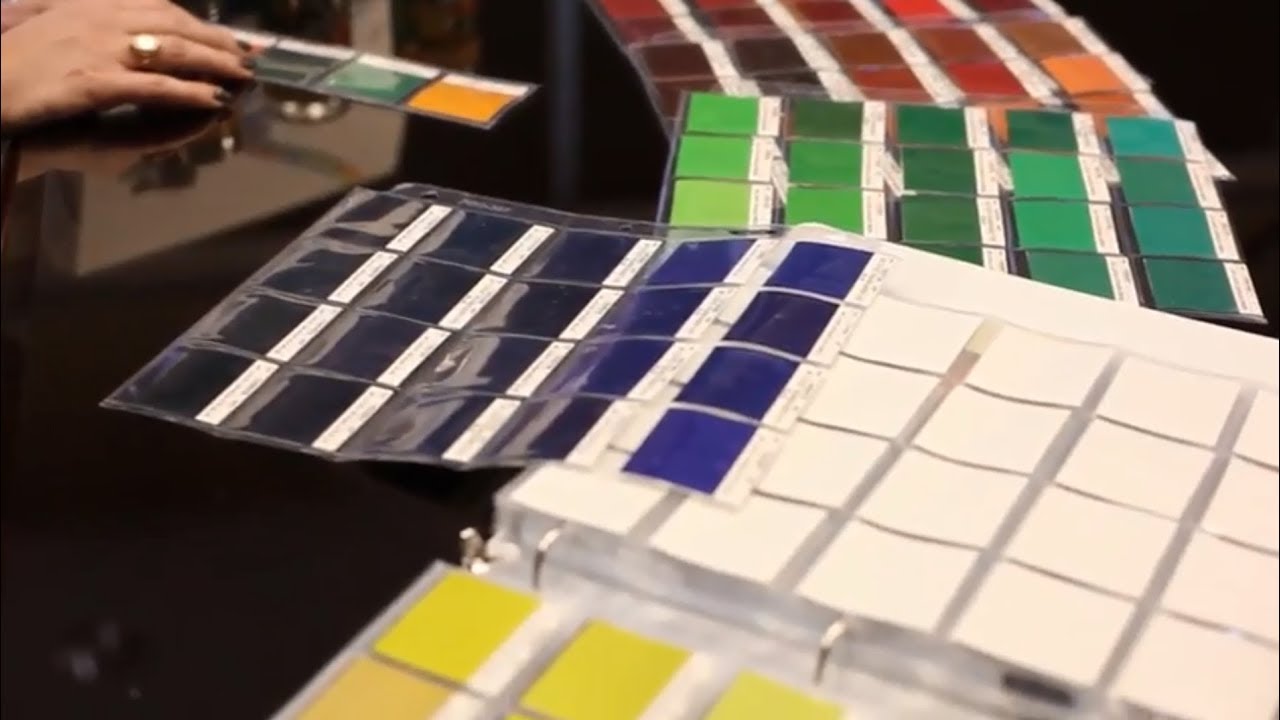

The term color management refers to the process used so that color reproduction is exact and matches the original design with true and accurate color. It is an important consideration with any printing or media project. The colors displayed can be crucial for the best possible project or campaign outcomes. If there is a lack of consistency or your colors do not appear the same shade in all of the printed materials as they do on your computer screen then this can be a big problem for brand owners.

Best Practices for Color Management

Best Practice #1: Align your partners around a common methodology

Complex, global supply chains and the ongoing growth and sophistication of packaging presents a unique challenge to brand owners: How can they work with their packaging providers to ensure that color and branding guidelines remain consistent across multiple geographic locations, packaging substrates, and printing technologies? Packaging printing is different from an agency creative board. It’s not easy to translate color from digital to physical and across printing methods and packaging substrates.

“Color management” applies to assorted measurement tools and software programs that are used to calibrate print machines to make sure that the colors specified and used by designers and brand managers match the colors used in production by printers and packaging providers. Defining the systems, tools, programs, and reference materials you are using with your packaging supply chain partners—including brand owners, packaging converters, and printers—will provide the necessary parameters and targets to ensure consistent and repeatable color matching on most every substrate.

Our INX Color Perfectionists use the G7 method for achieving visual similarity across all print processes, substrates, inks, and devices. G7 is IDEAlliance’s industry-leading set of specifications for achieving gray balance and outlines the steps to implement (ISO) G7-based printing standards and additional metrics. If all print products have the same gray balance and neutral tonality defined by G7, they will look remarkably similar to the human eye, a key component in effective brand quality management. The results are a simple, yet powerful, way to match from proof to press.

We are finding that an increasing number of our customers, including CPG brand managers, are requiring their printers and converters to be G7 Master Printers. This qualification demonstrates that a printing facility has calibrated its equipment to G7 requirements and includes three levels of compliance: the fundamental G7 Grayscale, G7 Targeted, and the most stringent, G7 Colorspace. When using the G7 method, printers are often able to come up to color faster, reduce waste, reproduce jobs on different printing platforms, and match proofs across different print platforms.

Best Practice #2: Work with color experts

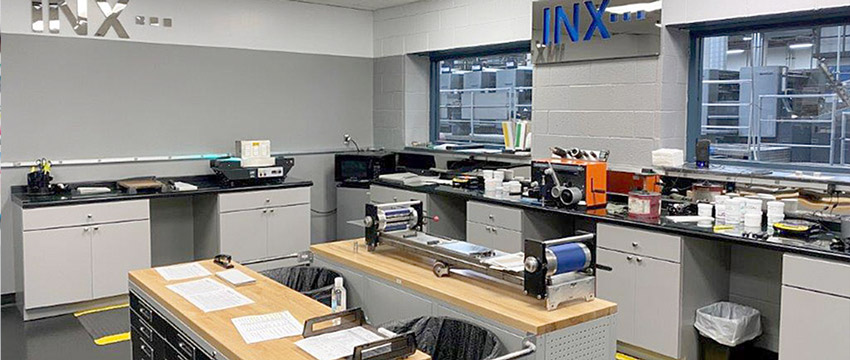

The biggest color management challenge many of our customers struggle with is the fact that ink mixing and color matching isn’t their core business. We get it. There are a variety of different issues that can affect print quality on any given job: The order that inks are put on a material can affect color consistency; the mixing of inks can affect color; and different coatings can affect color… to name a few. Many of our customers are interested in a plug-and-play solution or employing a combination of their in-house team together with our experienced on-site ink and color specialists in their very own inplant ink room on a daily basis. This takes them out of the ink and color management business and puts their focus back on their core business.

DOWNLOAD

Ink room management solutions that increase your efficiencies and reduce cost

Download Brochure

Best Practice #3: Commit to education and training

Lack of education and training—both on the G7 specifications and on various equipment and software programs—is also a common color management challenge encountered in the press room. When INX conducts a G7 session at a customer’s facility, our technical Color Perfectionists train their team members, identify the countless touchpoints within that printer or packaging converter’s operations impacting the consistency and repeatability of color, and recommend new procedures and process management best practices to help them overcome any barriers currently keeping them from creating and maintaining consistent color matching on the various substrates they are using.

While the standardization of color in printing is nothing new, changes in that space – refinements, new tools, new approaches – as well as the controllability of digital printing, have served to bring printed colors increasingly close to their mathematically-measured ideals. To familiarize yourself with industry color standards in addition to G7, we recommend reading our blog post Color Standards: Taking the Chaos out of Color.

Best Practice #4: Invest in and maintain quality equipment and software

Another frequent problem we encounter in the press room that directly impacts color quality is the type and quality of equipment being used (rollers, blankets, plates, etc.). The following lists our top ten recommendations for your equipment and devices in order to ensure your client’s exact color specifications are reproduced consistently:

- Invest in state-of-the-art color measurement instruments and software—including G7 certification.

- Each press should be color calibrated to G7 specifications.

- Each proofing device should have a G7-based ICC profile.

- Make sure your spectrophotometers are properly calibrated.

- Make sure you have a spectrodensitometer on each press.

- Have a scale or measurement on the printed product to verify it is to specification.

- Use blanket cameras to inspect for defects and a densitometer to inspect the density of the ink ensuring it matches the standard.

- Employ color inspectors to ensure colors match the standard.

- Incorporate some type of closed loop color system on each press to balance the sheet faster and reduce waste.

- Implement a software measurement program such as Measure Color or pressSign to help you stay consistent from sheet to sheet.

Best Practice #5: Establish effective communication protocols

Perhaps not surprisingly, another common color management challenge is communication, or a lack thereof. Color communication between brand managers, packaging designers, and packaging printers can quickly become problematic without the right people and processes in place to ensure that the precise color information is delivered throughout the supply chain. This becomes even more challenging as your supply chain becomes more complex with partners around the globe who are speaking different languages, in different time zones, working with different factories with different processes in place, and varying approaches to quality control. Although it may seem obvious, it’s not always so straightforward to make sure that the color you communicate to one partner is the same at every point along your supply chain where information is exchanged.

Best Practice #6: Implement a color management workflow

As a leading ink and coating supplier with a team of Color Perfectionists, our focus is dedicated to helping brand owners, graphic designers, packaging providers, and printers deliver brand colors accurately and consistently all across the globe. When we conduct an audit of a customer's press room and color management process, we frequently uncover workflow procedures that need to be modified in order to reduce the probability of color inconsistencies and quality issues and improve efficiencies in their color management process. The following are fundamental color management workflow recommendations to help establish or enhance your color management method:

- When a print job is run for the first time and the color is approved, that print sample should be used as the standard for any repeat jobs in the future. This standard is a sample that was produced with your press, your substrate, and your ink.

- Target color values should be established from actual samples printed on a production press in your environment rather than from a PDF, lab print, Kodak, or some other color samples.

- For metal decorating, the ink maker should provide the first swatch to the brand owner (the INX Color Catalog can be utilized for accurate color selection on aluminum) and the provided/selected swatch(es) should be utilized for color qualification until the initial sample is created and sent to the brand manager for approval and once approval is received, ultimately becomes the standard.

- Ensure that your color management workflow allows you to put ink pre-sets into the job data and that you are able to import plate curve adjustment data while you are working on color calibration. Ink pre-sets are essential in make-ready on a job. Pulling up to color in 50 sheets or 250 sheets and trying to match is extremely frustrating for your press operators and adds additional inventory requirement and productivity degradation.

- Earn certification in the G7 methodology. Since moving from film to CTP, the G7 method has consistently demonstrated that you can achieve the same results as CMYK on many platforms. This is another area where INX can help. We are highly qualified in helping a new customer through the certification process and/or helping a customer become recertified.

- At a minimum, equipment calibration should be completed at the start of each shift and be calibrated based on the manufacturer’s recommendation. Calibrating spectrodensitometers should be performed daily. Closed loop press systems should be calibrated at least per week.

Conclusion

Today’s consumers have more choice, yet less time. Products are more difficult to differentiate, and consumers are becoming less brand loyal. Packaging is often the first and final purchase influencer. If you want to achieve consistent color quality that meets exacting specifications and makes stakeholders comfortable that the proof they sign off on will match the actual product on the shelves, having a successful color management system in place is essential.

If you are a brand owner, printer, or packaging provider, do yourselves, your business, and your partners a favor by making sure you have an effective color management system.

Visit INX Color Management Services and Solutions to see how we help our customers reduce costs, speed product to market, and improve their client’s brand image.

CONTACT

Solutions to reduce costs, speed products to market, and improve clients' brand image.

Contact a Color Management Rep