Four Tools to Optimize the Production of Can Labels

Proprietary tools that help metal decorators improve the color control process and increase production efficiencies from concept to can

Cans are becoming increasingly popular thanks to their recyclability, their expansion beyond the carbonated beverage and beer market into non-alcoholic and ready-to-drink products, and cost-effective production runs1.

The global beverage cans market size was valued at $35.72 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 5.1 percent from 2020 to 2028. The U.S. is the biggest market for beverage cans with the highest per capita can consumption in the world2. Because of our dominant position in the metal decorating industry, INX has a vast amount of metal decorating knowledge and experience and continues to dedicate exclusive resources to the metal decorating market as well as the performance of our inks and color management programs.

The Challenge

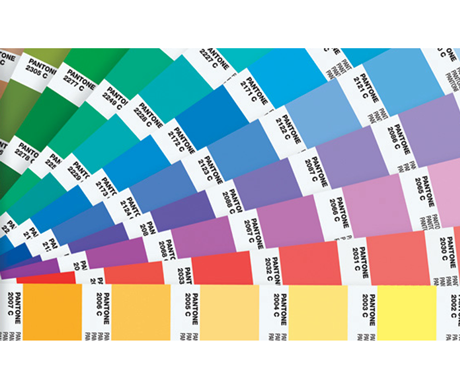

Brand owners want attention-getting labels with accurate and consistent color. Designers want fast and accurate color selection and to know that what they see at the infancy of the process is what they get on the printed can. Metal decorators want a cost-effective approach to color management, fast turn-around on color, and problem-solving tools. Achieving accurate and consistent color and process integrity from beginning to end-result, and efficient, cost-effective color management is made more difficult than necessary because of the lack of an industry-wide color standard and the limitations encountered when using paper guide standards.

Metal decorating is a very unique printing process and understanding how the substrate affects color is key in managing expectations. Paper guides don’t take into consideration the metal substrate, transparency, opacity, etc. Alternatively, choosing a color shade from a cloud or other online resource requires someone to interpret the shade in the paper guide. Varying shades often become ‘matches’ approved by different brand managers in different geographic regions to the same paper or cloud standard. There is not one approved shade. This adds further confusion by introducing varying shades for “one color standard”, often resulting in disappointment with the result of the color and ultimately being rejected by the brand manager, only to find that the process must then repeat itself. The visual below illustrates these challenges:

Color Selection Method based on Paper Guide/Cloud Library

1.Choose from paper guide

1.Choose from paper guide

Issue: Paper standards don't take into consideration the uniqueness of the metal substrate

2.Specify color from cloud-based color library matched to paper guides

2.Specify color from cloud-based color library matched to paper guides

Issue: Who decides what is a good match to paper-based standards?

3. Decorate can using cloud formula

3. Decorate can using cloud formula

Result = Rejected Colors

On metal substrate, color doesn't appear as brand manager intended

Optimization Tools

Many times, the majority of a company’s resources are allocated toward product development, and manufacturing and packaging/labeling processes can sometimes be an afterthought. Yet, packaging such as can labels are often just as important as the product inside when it comes to getting consumer attention and purchase. When you think about well-known brands, often the first thing that comes to mind is their logo and their packaging – especially the color.

INX Color Perfection® is a suite of products developed to assist brand owners, graphic designers, and metal decorators to achieve high-quality decorating on metal packaging. These products provide customers with a streamlined color management approach that addresses challenges posed by paper color standards. INX Color Perfection® is designed to ensure that the color and graphics envisioned by the designer or brand owner is properly captured by the metal can product on-shelf; and, that the processes used to produce that can are both efficient and cost-effective – throughout a regional, national, or global network.

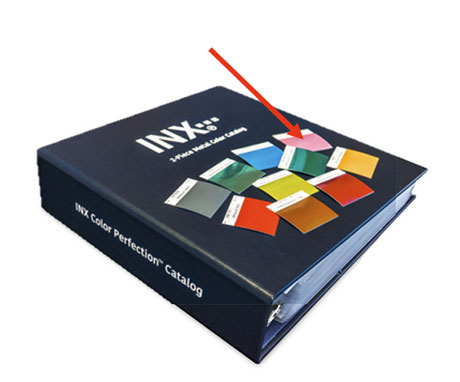

Tool #1: INX Color Catalog

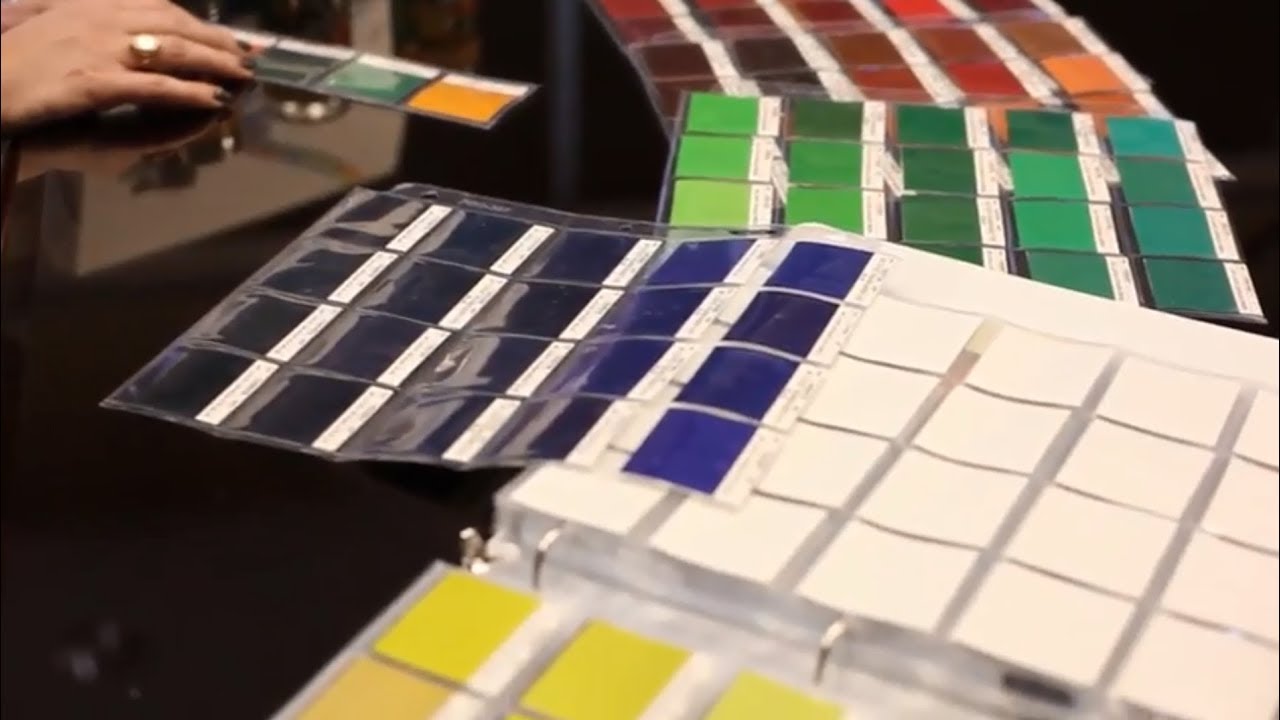

The backbone of INX Color Perfection is the INX 2-piece Metal Color Catalog created using INX best-in-class inks printed directly on aluminum. The INX 2-Piece Metal Color Catalog is the industry's first true color standard printed directly on metal. Using this catalog helps brand owners, designers, and metal decorators select, communicate, and approve color more efficiently, reduces lead times, and gets products to market faster. The catalog includes over 600 removable metal color swatches.

The INX Color Catalog is the industry’s first true color standard for beverage can design printed directly on metal.

Tool #2: Digital Color Library

The INX Digital Color Library gives designers and prepress teams access to the INX 2-Piece Metal Color Catalog colors for use during the design phase. The INX Digital Color Library is a plug-in preset which permits INX colors to be used within Adobe® design programs. Combined with the physical color catalog, the INX digitized Color Library can be utilized by designers at the very beginning of design creations. Even if designers plan to utilize conventional pilot processes, this tool can help provide better communication and speed-to-market.

INX Color Perfection

1.Choose Color from METAL color standards INX #1018796

Contains 600+ colors printed on metal, not paper ensures color is achievable on metal

2.Specify from INX Digital Color Library Plug-in

Each INX catalog color is digitized using patented technology and available for use in design programs

3. Decorate can using INX formulas

Each INX catalog color is digitized using patented technology and available for use in design programs

Result = Standardization of the Color Selection and Specification Process Approved Accurate Colors and Quicker Time-to-Market

LINK

INX Color Catalog is the industry’s first true color standard for printing on metal

Order Your Metal Color Catalog

Tool #3: Digital Proofing

Having the ability to produce and proof digital cans prior to the pilot and identify any required changes before a large production run increases the overall efficiency of both the design and the production processes. INX offers both direct-to-object proofing with the INX CP800 and can-wrap proofs with the Roland® VersaCAMM VSi Series. At INX, we’ve seen many can makers and design agencies adopt the CP800 to complement their current proofing processes. Since plates do not have to be created to utilize this proofer, customers have the ability to view their cans to more efficiently finalize graphics and color combinations without the expense and time involved with conventional proofing. Having a tool to help make these decisions in a more efficient manner allows brand owners, designers, and metal decorators to proceed with their current proofing processes—and ultimately final production runs—to bring those cans to shelves around the world.

Tool #4: Education

At INX, we believe education is crucial to standardization. Given the unique nature of our industry, many tools and resources are not available for reference. Fortunately, we’ve invested in and developed INX University, a free e-learning platform, available in eight languages, which provides access to educational materials to virtually everyone involved in the metal decorating supply chain. Courses range in content from INK 101 describing how ink is made, to content on color management. INX University is complementary to customers and partners of INX International and can be accessed at any time from your own computer or mobile device, providing a convenient way to learn! INX can provide detailed progress reports for our customers and their users through INX U as well.

LINK

INX University offers free online training for customers and partners.

See our course offerings

Conclusion

Metal decorating has multiple variables that affect color selection and reproduction, production processes, costs, and other problematic issues. We understand the importance of color and the role it plays in the consumer buying process. We understand the intricacies of metal decorating and that aluminum is not paper. INX International has invested in and dedicated exclusive resources to the metal decorating market and it is evident in our leadership position in the market. We believe establishing the first-ever metal decorating industry standards will drive increased optimization benefits and ultimately, faster, more successful product launches for our customers. INX Color Perfectionists are always available to help! Take a look around our site, where we have videos (such as the one below) and a wide variety of content and resources available for users!

Watch this video to learn more about INX Color Perfection from INX customers Temperance Beer Company and Misktonic Beer Company