How AI is Revolutionizing Manufacturing

Oden Technologies optimizes Manufacturing with AI

In manufacturing, efficiency, quality and process optimization stand as the cornerstones of success. With the advent of Artificial Intelligence (AI), industries are revolutionizing manufacturing processes with a new way of structuring and consuming information, bringing an exceptional opportunity to manufacturers. Oden Technologies has emerged as a trailblazer, transforming manufacturing data from a headache to an opportunity using AI. Let's delve into how Oden is reshaping the manufacturing sector with its cutting-edge AI solutions.

The Essence of Oden Technologies

Oden manages the intersection of chaotic manufacturing data, advanced AI, and industry specific needs. Under the leadership of co-founders Willem Sundblad and Peter Brand, Oden has a vision to empower manufacturers with actionable intelligence. The company offers comprehensive AI-driven solutions that enable optimization of production processes at the operator and engineering level. The innovative solutions integrate top-tier data aggregation and organization to deliver advanced analytics and recommendations, enabling manufacturers to optimize production across various metrics including throughput, quality, profitability, and sustainability closer to the production line.

Workforce Challenges in Manufacturing and the AI Opportunity

An average manufacturer creates millions of process and production data points per line, per day. Those data points represent billions of variables that affect decision making on the front-line, and can make the difference between a productive and an unproductive shift. Historically, manufacturing has leaned heavily on the intuition of its experienced employees to sift through data points to find the most productive way to operate. With mass retirement, and a changing workforce mix that leans heavier on the inexperienced, tools like AI can step in to cut through the noise and find optimization.

Oden’s AI applications find anomalies, detect opportunities, and present recommendations from billions of data points processed in real time in a highly scaled way that doesn’t take years of on-the-line learning or custom building. These are then presented in an easy to navigate, web-based UI to make real-time optimization, predicted quality, and finding the largest opportunity across lines incredibly easy for operators, managers, and engineers.

Unleashing the Potential of AI:

Oden’s AI solutions offer a plethora of functionalities tailored to meet the diverse needs of manufacturers:

Real-time Process Optimization:

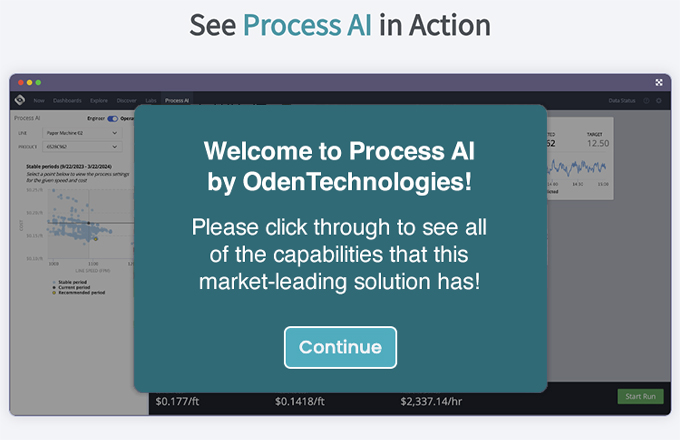

Process AI closes the gap between inexperienced and experienced operators, overcoming critical workforce challenges. Through advanced AI and Machine Learning, Oden’s Process AI identifies and surfaces the best process settings to use in real-time based on historical achievable runs and organizationally set goals and constraints. With real-time recommendations and predicted outcomes served directly to operators, Process AI ensures front-line workers have the exact information they need — when they need it— to achieve peak production.

Data and AI Made Useful For the Front-Line

The information operators need to be high performers, available in one click.

Process AI gives process recommendations based on real-time conditions directly to operators.

Real-Time & In-Depth Monitoring:

By continuously monitoring production processes, Oden's Factory Analytics solution provides manufacturers with unprecedented visibility into their operations. Factory Analytics is built for supervisors, plant managers, and process engineers. Factory Analytics includes a variety of off-the-shelf visualizations, dashboards, and advanced reporting capabilities to allow these functions to dive into their data and find opportunities for improvement or root causes of issues in one easy to navigate system. Factory Analytics provides supporting capabilities to Process AI so that the teams around operators have the information they need to improve production.

Top Performance Losses (example)

Previous week

12.37 hrs lost due to performance in below 5 product line combonations. 2.58 hrs lost due to performance in other 35 product line combonations.

| Line Name | Product Name | Output | Duration (hrs) | Perf. | Perf. Baseline | Tgt. Speed | Avg. Speed | Time Lost |

|---|---|---|---|---|---|---|---|---|

| Extrusion Line 2 | 875446E2 | 393,974.17 | 48.30 | 90.63% | 92.97% | 150.00 | 135.94 | 4.53 hrs |

| Extrusion Line 1 | 48B68B1F | 431,563.69 | 38.17 | 89.72% | 88.21% | 210.00 | 188.42 | 3.92 hrs |

| Extrusion Line 4 | 457F09EB | 317,997.41 | 26.05 | 92.49% | 91.04% | 220.00 | 203.47 | 1.96 hrs |

| Extrusion Line 4 | 22EEA916 | 484,082.87 | 39.48 | 97.31% | 97.61% | 210.00 | 204.34 | 1.06 hrs |

| Extrusion Line 4 | 9A8BB635 | 144,914.13 | 11.63 | 92.29% | 90.73% | 225.00 | 207.66 | 0.90 hrs |

Oden's Factory Analytics makes identifying areas of performance loss incredibly easy.

Data Management:

Without a strong data foundation, any AI or machine learning tools or use will result in hallucinations. This can cause errors in decision making, and distrust in the solutions all together. Oden's Data Engine has been built for manufacturing data, and only manufacturing data. It combines and aligns data from streaming process sources and contextual production systems, then processes that data through numerous data cleaning and enrichment tools such as outlier identification, dynamic storage, automated labeling and timing of machine status and events. Through this, the Data Engine turns data headaches into opportunity in a turnkey and scalable way. It serves as the basis for future products as Oden continues to invest in innovation and solving new challenges in the manufacturing industry.

Strategic Partnership Drives Manufacturing Transformation

In early 2024 INX International participated in a groundbreaking $28.5 million Series B funding round for Oden, spearheaded by Nordstjernan Growth. This significant investment and collaboration between INX and Oden heralds a new era of innovation and efficiency in manufacturing, demonstrating the power of strategic partnerships in driving industry-wide transformation.

For INX, partnering with Oden translates into tangible benefits for their operations. By leveraging Oden's software, INX is enhancing product quality and consistency across batches while maximizing throughput. Moreover, INX is actively contributing to Oden's product roadmap evaluation and piloting new offerings, enabling Oden to improve, test, and scale releases even faster.

Shane Bertsch, INX's senior VP of Innovation and Strategy, emphasizes the transformative potential of Oden, stating, "We view Oden Technologies as a platform for enabling industry 4.0-level efficiencies and quality. INX believes that machine learning and AI can contribute to several aspects of our business. It will augment our resources to become faster and more efficient in driving innovation, and deliver more value to INX customers."

A pilot program between Oden and INX yielded impressive results, including a 13% improvement in asset availability, a 71% reduction in changeover times, and a remarkable 40% increase in line speed. These solutions are scalable from a single line to enterprise-wide deployments, showcasing their versatility and efficacy.

Willem Sundblad, Oden’s co-founder and CEO, says, “INX has been a great customer and partner to Oden. Our shared vision of empowering the front-line to make production improvements through data has helped us improve our offerings in several ways. We are thrilled to have INX on our cap table as an investor, and their support reinforces the value of Oden’s solutions for enterprise manufacturing companies.”

Case Study: INX International Ink Co. & Oden Success Story

The Impact of Harnessing Data & AI in Manufacturing

The integration of Oden’s solutions has empowered manufacturers to use data and AI to drive key OEE improvements, such as:

- Enhanced Efficiency: By leveraging AI to optimize production processes, manufacturers have witnessed significant improvements in efficiency, throughput, and resource utilization.

- Improved Quality: Oden's AI-driven quality optimization tools have enabled manufacturers to uphold the highest standards of product quality while optimizing for cost and throughput.

- Reduced Downtime: Through downtime categorization, automatic labeling, and analysis, manufacturers have mitigated unplanned downtime.

- Empowered Workforce: Oden's AI platform empowers manufacturing teams with actionable intelligence, enabling informed decision-making, reducing the learning curve to become high performers, and fostering a culture of continuous improvement.

Conclusion:

As manufacturing continues to adopt and use advanced technologies, effective use of data and AI will remain a cornerstone of innovation and competitiveness. Oden stands at the forefront of this transformation, developing advanced AI-driven solutions to revolutionize traditional manufacturing processes, increasing efficiencies, quality and process optimization at the line level. As manufacturers embrace AI-driven solutions, they will undoubtedly unlock new opportunities for growth, differentiation, and sustainable success in an increasingly competitive marketplace.

Learn more about Oden at oden.io.