Pigment Inks for Digital Textile Printing

Enhancing Sustainability through Inkjet Technology

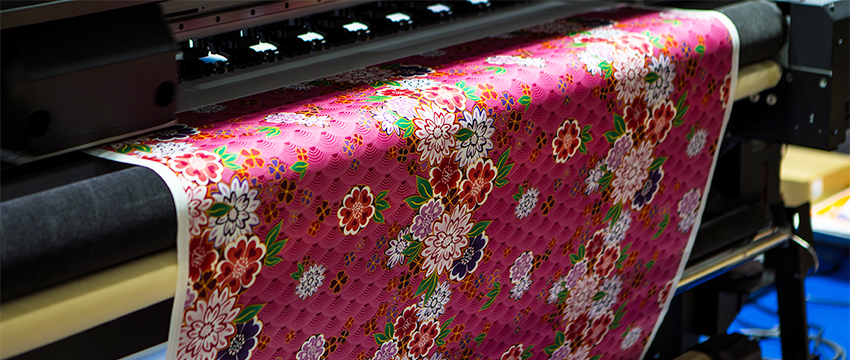

Digital textile printing has revolutionized the world of textiles since the early 2000s. It has enabled designers and manufacturers to bring their creative visions to life with unprecedented precision and efficiency. It has also emerged as a sustainable alternative to traditional printing techniques, offering numerous advantages in terms of reduced energy consumption, water usage, and waste generation.

Pigment inks, in particular, have gained significant popularity in the digital textile industry due to their unique characteristics, versatility, and compatibility with eco-friendly inkjet technologies. With their ability to create stunning designs while minimizing environmental impact, these inks are reshaping the landscape of the textile industry.

This article delves into the sustainability aspects of pigment inks, focusing on inkjet technology and its contribution to minimizing environmental impact in terms of energy and water consumption. It also provides insights into the printed volume per annum, highlighting the growth and future potential of digital textile printing.

Textile printing market size

The global market for textile printing is projected to grow significantly, driven by factors such as population growth, increasing purchasing capability, and moving fashion trends. Amid the COVID-19 crisis, the market was estimated at approximately 22 billion square meters in 2020. It is expected to reach 28 billion square meters by 2026, growing at a CAGR of 4.3%.

The screen printing segment is projected to reach 24.6 billion square meters, growing at a notch below 3% CAGR. However, the outlook for the digital printing segment is much more optimistic. It is expected to grow at 16.5% CAGR, accounting for a 7.8% share of the global market. The adoption of digital textile printing has witnessed substantial growth in recent years. According to the 2020 FESPA Print Census1, approximately 64% of textile printing businesses reported an increase in digital textile printing volumes. This trend indicates the rising demand for digital textile printing as a sustainable and efficient solution in the industry.

The market size of digital textile printing, including pigment inks, has also steadily expanded. According to Grand View Research2, the global digital textile printing market was valued at $2.31 billion (USD) in 2019 and is projected to reach $8.76 billion (USD) by 2027, growing at a CAGR of 18.9% from 2020 to 2027.

This significant growth demonstrates the increasing acceptance and adoption of digital textile printing technologies, including pigment inks, on a global scale.

Understanding pigment inks and factors influencing usage

Pigment inks have ushered in a new era of vibrant and long-lasting color in textile printing. Unlike their dye counterpart, these inks penetrate the fabric fibers and bond with them, resulting in an exceptional color saturation that resists fading even after multiple washes. From striking hues to subtle tones, pigment inks empower designers to unleash their creativity and bring their vision to life with unparallel brilliance.

Understanding the specific requirements of the chosen fabric is crucial to achieving optimal results with pigment inks. Some inks recently introduced to the marketplace by premium global manufacturers can be used on un-treated fabrics, making them even more sustainable and efficient. A good representation of what is available was on display at ITMA, the world’s largest international textile and garment technology conference that took place in Milan in June..

Water-based pigment inks are compatible with various digital textile printing technologies, such as direct-to-fabric inkjet printers commonly referred to as DTF printers. It is essential that the printer and ink formulations are well-matched to ensure the best quality, the proper ink ejection, color accuracy, and adhesion to the fabric. Proper printer maintenance and calibration also play a significant role in achieving optimal print quality, while preserving printer’s durability.

In the past, these inks were traditionally difficult to use with formulations of dubious quality. Today, several manufacturers have reached a performance level that allows for large scale continuous use.

In DTF printing, the pigment ink is applied directly onto the fabric using specialized inkjet printers. Fabric preparation, including pre-treatment if necessary, is crucial to achieve satisfactory results. Proper curing and fixation methods, such as heat or steam fixation, are employed to ensure colorfastness and durability.

Pigment inks only require heat for a relatively short time before you can start fixing them onto the fabric. This is another important feature of pigment inks compared to other chemistries. The post-print process is very easy and less demanding in terms of energy.

Inkjet technology and sustainability

Let’s begin with energy efficiency. According to a 2018 study by Almeida et al.3, digital textile printing with pigment inks can reduce energy consumption by up to 30% compared to conventional printing methods.

Inkjet technology in digital textile printing offers significant energy savings compared to traditional printing methods such as screen printing or rotary printing. Inkjet printers operate using precise droplet ejection mechanisms, allowing for targeted ink deposition and minimizing energy-intensive processes like platemaking or screen preparation.

Water conservation has become a more important issue in the last decade. Digital textile printing with pigment inks significantly reduces water consumption compared to traditional printing techniques. Unlike screen printing, which requires extensive washing and rinsing processes, inkjet technology enables precise ink placement, eliminating the need for excessive water usage.

A 2019 study by Hincapié et al.4 estimated that digital textile printing can reduce water consumption by approximately 60-70% compared to conventional methods. There is a notable reduction in water usage between inkjet pigment inks and inkjet dye-based, but it depends on various factors such as the specific printing process, fabric type, design complexity, and equipment efficiency.

However, it is widely acknowledged that inkjet pigment inks offer substantial water savings compared to inkjet dye-based inks. Inkjet reactive inks are commonly used for printing on natural fibers such as cotton, and require an additional step called steaming or washing to fix the dyes onto the fabric. This fixing process involves using large amounts of water to remove excess dye and ensure colorfastness.

On the other hand, inkjet pigment inks do not require a separate fixation step, eliminating the need for excessive water usage associated with reactive inks. The absence of washing processes and the targeted ink deposition of pigment inks significantly contribute to these water savings. However, it is important to note that the exact reduction may vary based on specific printing conditions and the level of optimization in inkjet printing systems.

Digital textile printing with pigment inks also minimizes waste generation by ensuring precise ink placement and reducing overprinting. Unlike traditional printing techniques, inkjet technology allows for on-demand printing, eliminating the need for excessive inventory and reducing waste due to obsolescence.

Pigment inks printed volume potential

The adoption of digital textile printing has witnessed substantial growth in recent years. According to the 2020 FESPA Print Census1, approximately 64% of textile printing businesses reported an increase in digital textile printing volumes. This trend indicates the rising demand for digital textile printing as a sustainable and efficient solution in the industry.

The market size of digital textile printing, including pigment inks, has also steadily expanded. According to Grand View Research2, the global digital textile printing market was valued at $2.31 billion (USD) in 2019 and is projected to reach $8.76 billion (USD) by 2027, growing at a CAGR of 18.9% from 2020 to 2027.

This significant growth demonstrates the increasing acceptance and adoption of digital textile printing technologies, including pigment inks, on a global scale.

Sustainability initiatives and certifications

Ink manufacturers are continuously striving to develop more eco-friendly and sustainable ink-jet pigment ink formulations. Pigment inks are a driving force behind the ongoing eco-print revolution in the textile industry. These formulations focus on reducing or eliminating harmful substances, volatile organic compounds (VOCs), and heavy metals. The absence of screen emulsions, chemical washes, and extensive dye baths reduces the environmental impact associated with chemical usage and disposal. Their water-based formulations significantly reduce the environmental footprint compared to solvent-based alternatives, making them a preferred choice for environmentally conscious manufacturers.

Various certifications and standards exist to promote sustainable practices in digital textile printing. The Global Organic Textile Standard (GOTS) and Oeko-Tex Standard 100 are two widely recognized certifications that ensure environmentally friendly and socially responsible production processes. These certifications cover aspects such as the use of eco-friendly inks, reduction of energy and water consumption, and adherence to strict chemical standards.

Summary

In the ever-evolving world of textile printing, pigment inks have emerged as a game-changer, offering unparalleled vibrancy, enduring quality, and a sustainable approach to production. With their versatility, adaptability, and capacity for innovation, these inks have cemented their position as the driving force behind the transformative shift towards eco-conscious and long-lasting printing solutions. As the industry continues to be powered by pigment inks, a future where vibrant, sustainable, and resilient textiles are the norm seems more within reach than ever before.

1FESPA. (2020). FESPA Print Census 2020: Report Highlights.

2Grand View Research. (2020). Digital Textile Printing Market Size, Share & Trends Analysis Report by Printing Process (Direct, Discharge, Resist), by Application, by Region, and Segment Forecasts, 2020 - 2027.

3Almeida, A., Ferreira, J., & Amado, A. (2018). Energy Consumption in the Digital Textile Printing Industry. Sustainability, 10(11), 4139.

4Hincapié, I., Carrillo, P., Durán, A., & Turégano, M. (2019). Environmental Impact Assessment of Digital Textile Printing: A Case Study. Fibers, 7(5), 39.