Special Effect Printing for Beverage Cans

Specialty Inks Bring Specialized Results for Beverage Cans

Decoration of metal packaging—a necessary exercise in product identification—has evolved significantly in recent years. By using specialty inks, designers and producers of aluminum cans have access to solid opportunities to produce brand awareness and increase value. With so many canned beverages on store shelves today, being seen means presenting graphics and messaging that more effectively say, “buy me.”

While the presence of printed metallic containers is nothing new, opportunities to incorporate special effects into the design have changed the model. Where the previous approach was all basic identification, the ability to economically produce a more engaging product has brands and designers reaching for the possibilities.

For metal decorating today, opportunities exist for package printers to go the extra mile, printing special effects that help the product appeal to the senses, gain attention, engage customers, and even protect brands. Special effects differentiate the product from other, similar types of products on the store shelf, and help package printers differentiate themselves from their competitors.

New Options in Can Design

Using the standard, two-piece aluminum can as the “canvas,” special effect ink technologies—through the careful collaboration of brand managers, designers, and package printers—can be used to produce astounding new innovations in packaging with benefits that transcend simple decoration.

Show-through & Opaque Effects

Allowing visual space for the shiny, metallic finish of the metal container to show through can provide a metallic look without the need for metallic inks. Similarly, opaque inks block the container's metallic nature, in some cases giving the look of an elaborate decal. While these effects can be produced using standard dry offset inks formulated for aluminum cans, Alexander Folloso, Director, Metal Decorating Technology for INX says, that achieving a high-opacity underbase may require a “double hit” of white ink.

Matte or Gloss Over-Varnish

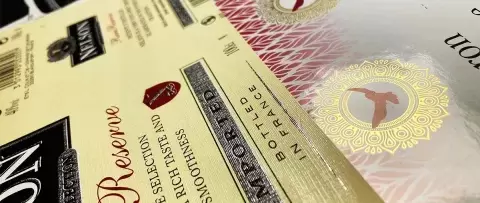

Using a printed finish—whether matte or gloss—gives package producers the ability to do spot effects, including the non-reflective look of non-reflective “flat” paint; or the reflective color-popping glossy effects that heighten the perceived value of the product. For example, wine producers Dark Horse and Underwood use gloss and/or matte finishes in their canned products.

Matte and gloss finishes can increase the perceived value of some products.

Fluorescent Inks

Fluorescent inks feature colors that, while startingly “bright” to begin with, will fluoresce when exposed to black light. Enterprising designers and package producers have used these inks to help product branding “glow” within the confines of bars, nightclubs, and other spaces. This helps brands identify themselves, even within dark settings, with the aid of so-called black light. INX offers its LoVOC Black Light Inks for producers seeking to expand into this opportunity.

Thermochromic Inks

Since 2009, cans of Coors Light have included thermochromic inks, (inks that change color with temperature), to indicate the product is at or below optimum drinking temperature of 46 degrees Fahrenheit. When the mountains printed on the can are blue, the ink tells us the beer is ready. INX, through an ongoing partnership with Chromatic Technologies, a producer of thermochromic, photochromic and reveal inks, serves package producers with an ink solution that provides the capability to explore the benefits of thermochromic effects.

Messaging with thermochromic inks: the blue mountain means the beer is cold.

Tactile Effects & Textures

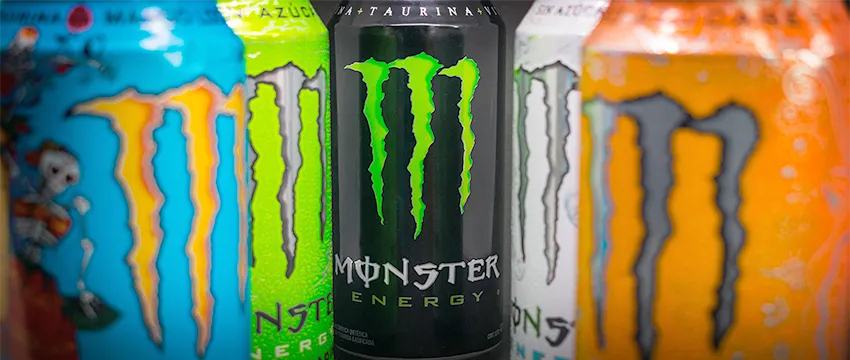

While printing is often seen as an activity that stimulates the visual sense, specialty ink systems can print textures, creating tactile effects that simulate the sense of touch. This can also be used for container decoration to simulate embossing, or to create finishes that extend branding or increase perceived value. Tactile effects have been used by energy drink producer Monster to heighten the look of its products. Tactile Plus inks from INX are formulated explicitly for two-piece metal decoration.

Glow in the Dark

Phosphorescent effects, commonly known as “glow in the dark”, uses inks that will glow for a period after they have been exposed to natural or simulated light sources. Like fluorescent inks, these inks can provide a secondary look or reveal hidden details displayed when the ambient environment is dark. The glowing effect will fade over time but can be reactivated by re-exposing it to light.

Brand Protection and Authentication

A variety of printed effects can be produced to authenticate products. This can be as simple as using a difficult-to-match specialty substrate or as complex as hidden “markers” that show only when the product is exposed to specific wavelengths of light. This is particularly useful with luxury products applied using an inkjet process, a covert security ink from INX and VerifyMe provides brand owners with time-sensitive logistics, authentication, supply chain monitoring, and data-rich consumer engagement features using unique smartphone-readable codes on their products. Read Protecting Your Packaging and Your Brand with Security Inks.

Retort Inks

While it is easy to view the two-piece aluminum can primarily as a vessel for cold beverages such as soft drinks, flavored seltzer, and a myriad of beers, they are also used to hold dairy-based products, that require the product to be brought to a temperature of 230-275 degrees Fahrenheit for a specified time to sterilize the product. Not all inks, however, can withstand temperatures for this extended period. Retort II inks from INX are specially formulated to withstand these production temperatures allowing producers to undertake required sanitary steps while maintaining the integrity of printed branding.

Evolving Technologies

Technology has evolved for dry offset aluminum can printing and the special effects outlined above illustrate increased opportunities that will take packaging in new and exciting directions. As a leader in inks for aluminum can decoration, INX International serves at the forefront of new technologies, expanding what is possible.

To learn more about special effect inks and how they can provide additional opportunities for your metal decorating operation, contact INX or email us at [email protected].