GelFlex EB™ Inks

Surface print ink system for CI flexo printing

GelFlex∙EB is a surface print ink system for CI flexo printing that provides superior print quality similar to gravure while providing a crosslinked, durable ink film. The resulting effect eliminates the need for a lamination layer, reducing cost and total package weight while improving recyclability.

What makes GelFlex•EB Revolutionary

Printers today are under constant pressure to maintain graphics quality while delivering year-over-year cost reductions. GelFlex·EB™ Ink can give you: cost reduction through ink savings, waste savings, and productivity gains, combined with better image quality and smaller dots. It offers package light-weighting opportunities similar to other energy curable ink systems with the added advantage of elimination of photoinitiator by-products. And all while decreasing emissions compared to standard solvent-based inks.

Further cost savings measures can be realized through elimination of lamination layers for flexible packaging and introduction of various decorative and special effects coatings.

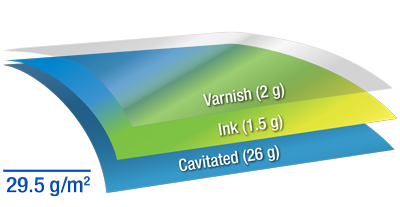

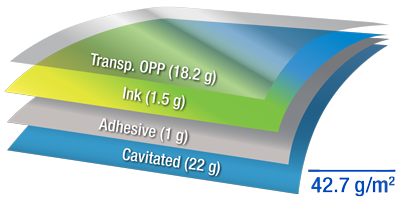

Package Lightweighting

GelFlex•EB Inks

Traditional

Top Benefits of EB Technology for Flexible Packaging

Safe and Sustainable

- Low migration food packaging compliant

- Lowest odor, taint, and extractable levels

- Drastic solvent reduction

- Less Ink consumption and waste

- Reduces package weight with lamination layer elimination

Better Print Quality

- Finer line screen & lower BCM anilox for higher resolution and tonal value

- Less dot gain for higher details in full color images, brightness and smooth vignettes

- Smooth ink laydown, reduction in graininess, and higher solid ink density

- Highest physical properties (gloss, resistance) allowing lamination replacement

Efficiencies Cost Savings

- Ultra-high press speeds

- Instantaneous cure

- Less energy consumption

- Less ink consumption

- Elimination of hot air dryers

GelFlex EB sales sheet

GelFlex EB sales sheet