How Inks and Coatings Can Enable Mono-Material Packaging

Mono-material packaging offers numerous advantages

The demand for recyclable and sustainable packaging that reduces waste continues to grow, further driving the need for designing new package structures. The industry’s shift towards mono-material solutions is driven by the growing awareness of environmental issues, including plastic pollution. Mono-material packaging is gaining momentum as a promising solution to address this issue. In this article, we will explore the role of inks and coatings in enabling mono-material packaging and how they contribute to a more eco-friendly and sustainable packaging solution.

Flexible packaging recycling challenges

Flexible packaging, characterized by its lightweight, versatile, and often convenient design, has been a staple in various industries—including food and beverage, pharmaceutical, and consumer goods—for decades. It commonly involves the combination of multiple materials like plastics, films, and foils to create pouches, bags, and wrappers which offer barrier properties, extend shelf life, and provide user-friendly features. While flexible packaging has been instrumental in reducing material usage and transportation costs, the multi-material composition poses significant challenges for recycling.

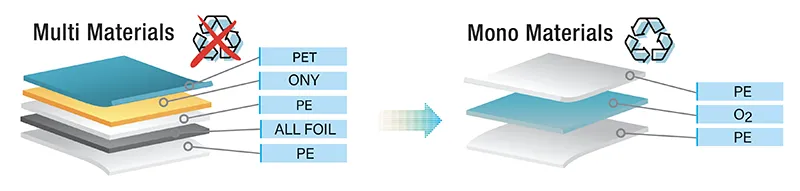

In the flexible packaging industry, the quest for mono-material solutions is particularly crucial. The traditional multi-layered structures of flexible packaging, often made up of different types of plastics and other materials, hinder the efficient recycling of packaging waste. The difficulty of separating and processing these materials has led to a considerable amount of flexible packaging ending up in landfills or incineration, contributing to environmental concerns.

What is mono-material packaging?

Mono-material packaging refers to packaging solutions made from a single type of material throughout its composition, as opposed to a combination of different materials like plastic, paper, and aluminum. Commonly, mono-material packaging involves the use of plastic or polymer. The objective of mono-material packaging is to facilitate the recycling process because it eliminates the need to separate different materials.

The role of inks and coatings in mono-material packaging

Inks and coatings play a vital role in making mono-material packaging feasible and effective:

- Labeling and Printing: In mono-material packaging, clear and informative labeling is crucial for consumer understanding and recycling. Inks are used to print important information such as product details, branding, barcodes, and recycling symbols directly on the packaging.

- Barrier Coatings: In some cases, mono-material packaging may require barrier coatings to protect the contents from external factors like moisture, oxygen, and UV light. Barrier coatings can be applied to the packaging material to extend shelf life and maintain product quality. These coatings are typically designed to not inhibit the process of recycling. The many benefits of barrier coatings include package protection, food preservation, package lightweighting, and recycling.

- Inks that eliminate lamination: Inks can play a critical role in reducing layers and enabling recycling. Innovations like INX International’s GelFlex™ EB Curing Inks can be used. The fluid, gel-based inks for CI flexo printing cures rapidly after printing, providing effective high-speed wet ink trapping. The combined structure is then cured by a single EB dryer at the end of the press. Resistance properties are achieved with surface printing, eliminating the need for a lamination layer, enabling package lightweighting and improved recyclability.

- Laminates for Durability: The use of laminates in mono-material packaging introduces a strategic approach to maintaining the desired barrier properties while still adhering to the principles of a single material composition. Laminates involve bonding layers of the same material in various thicknesses or formats, allowing for the creation of a mono-material structure with enhanced durability properties.

Benefits of mono-material packaging

Mono-material packaging offers numerous advantages, including:

- Improved Recycling: With a single material, mono-material packaging is easier to recycle. It streamlines the recycling process and reduces contamination caused by mixed materials.

- Reduced Environmental Impact: The use of eco-friendly inks and coatings further reduces the environmental footprint of packaging, contributing to a more sustainable approach.

- Waste Reduction: Mono-material packaging minimizes waste by eliminating the need for multi-material composites, which can be challenging to recycle.

In a typical example, a multi-material laminate composed of PET/PE can be replaced with a barrier-coated OPP/CPP or OPE/PE structure. This new structure makes recycling easier by using similar materials while still maintaining the oxygen barrier properties of other multi-material structures.

In a typical example, a multi-material laminate composed of PET/PE can be replaced with a barrier-coated OPP/CPP or OPE/PE structure. This new structure makes recycling easier by using similar materials while still maintaining the oxygen barrier properties of other multi-material structures. - Consumer-Friendly: Clear labeling and recognizable materials make it easier for consumers to understand and participate in recycling efforts.

- Compliance with Regulations: As governments and organizations worldwide focus on sustainability and recycling targets, mono-material packaging aligns with regulations and initiatives aimed at reducing plastic waste.

Conclusion

Mono-material packaging emerges as a pivotal solution in the pursuit of sustainable and eco-friendly packaging. By employing a single material throughout the package structure, the industry addresses the challenges posed by the recycling complexities of multi-material packaging. Eco-friendly inks, barrier coatings, adhesives, and laminates help create packaging that is not only recyclable but also reduces waste, environmental impact, and carbon footprint. As the demand for sustainable packaging continues to grow, the role of inks and coatings in enabling mono-material packaging will become even more critical in shaping the future of the packaging industry.

![Shrink Labels and Recycling [Shrink labellled bottles]](/sites/default/files/styles/large/public/2024-04/INX_shrink_blog850x360.jpg?itok=Qsx6qEqs)